Geotechnical Engineering - Facilities

Last Updated:

About Soil Mechanics Laboratory:

Soil Mechanics Laboratories are set up on a total area of 500 m2 including controlled temperature (70m2) and humidity rooms (19m2). Some of the equipment are connected to data loggers for automatic recording.

Available equipment for soil tests:

• Standard equipment for soil classification,

• Automatic proctor compaction and CBR machine

• A small shaking table to assess maximum density of granular soils

• 4 conventional triaxial testing units (Wykham Farrance and ELE) for testing soil samples up to 10 cm diameter,

• Automated triaxial testing unit (VJ Tech)

• 4 direct shear machines one with residual testing attachment

• 1 large direct shear setup (30x30cm specimen with clamps for geosynthetics),

• 16 regular, 2 heavy-duty, 1 unsaturated 1-D compression/consolidation testing machines,

• Laboratory vane shear apparatus,

• Unconfined compression test setup

• In-situ and laboratory wedge shear testing devices developed at METU.

• Pressure plate extractor

• Infiltration column with tensiometers

• Hanging column setup

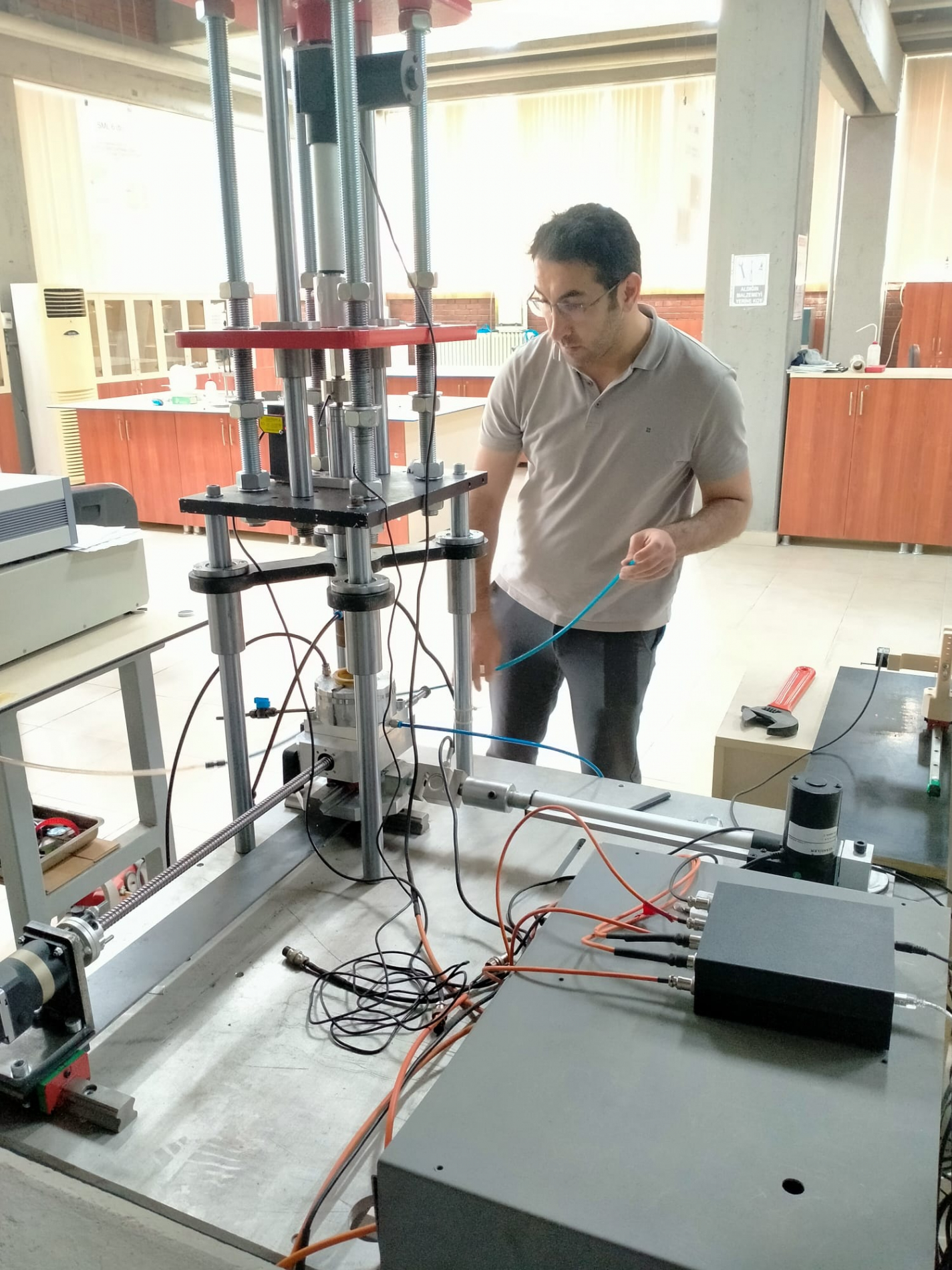

• Hollow cylinder dynamic torsional shear

• Bidirectional dynamic simple shear

• Unsaturated triaxial test setup (axis translation suction control and volume change measurement),

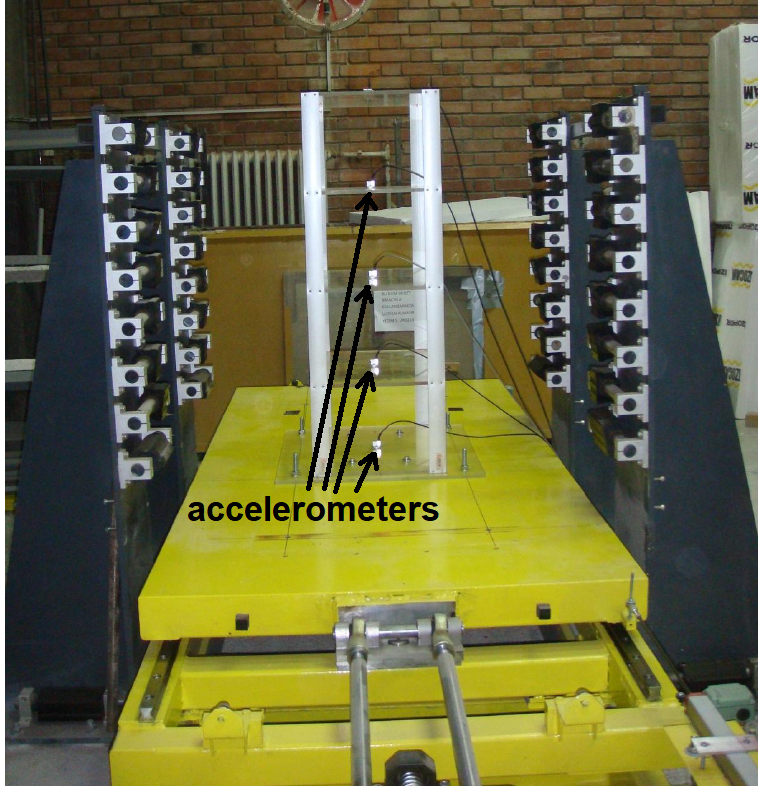

• A shaking table with a laminar tank dimensions of 1 m by 1 m by 1.5 m, to study dynamic earth pressures under harmonic base motions. The shaking table system can perform uni-directional dynamic experiments with random motion excitation in a fully computer controlled manner with a maximum frequency of 5 – 7 Hz (depending on the payload, maximum 2 tonnes), an amplitude of ±300 mm and at a maximum acceleration of amax = 0.3g

• Rainfall intensity-controlled flume setup (2 m long)

• Scaled model testing tanks of various sizes upto 1m3

Software:

FLAC, Proshake, DeepSoil, SeismoSignal, Teldyn, Telsta, QUAD4M, MIDAS, FLUSHPLUS, PLAXIS 3D, Rocscience, SoilVision, GeoSlope GeoStudio, LPile, GEO5