Educational Purpose Formwork Study

Scaffold and Formwork Manufacturers Association (IKSD) and METU Civil Engineering Department

Educational Formwork Study (IKSD - Scaffold and Formwork Manufacturers Association)

Purpose and content of the study:

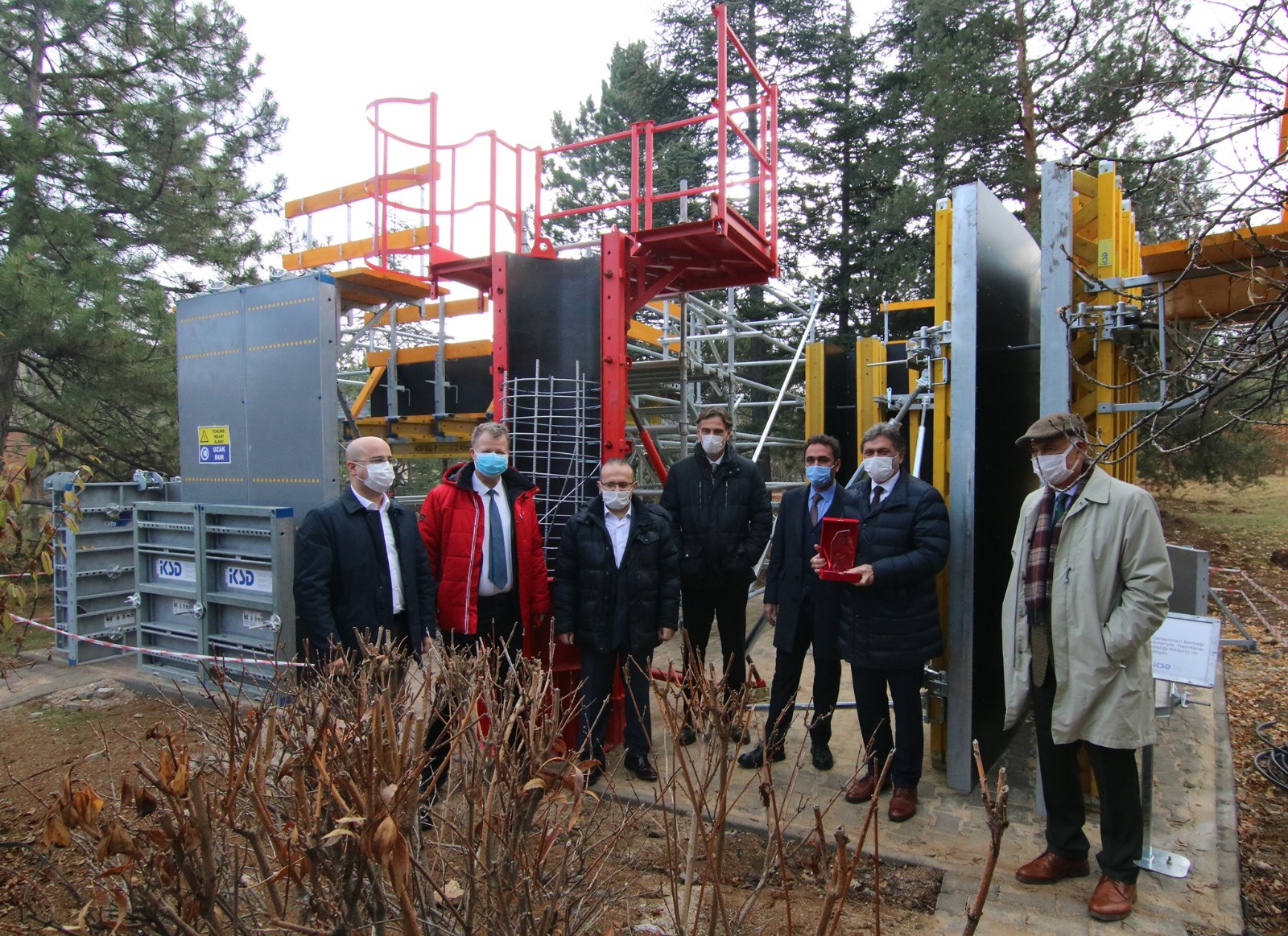

The Scaffold and Formwork Manufacturers Association (IKSD) aims to support our country's development, increase our competitiveness and exports in international markets, and address industry problems, solutions, and sectoral collaborations. The METU Civil Engineering Department aims to equip Turkey's best students with the most up-to-date knowledge, targeting excellence in problem-solving, design, implementation, management, and creativity, both domestically and globally. In a first for Turkey, a study has been conducted for our students to see examples of the latest formwork and scaffolding techniques, enhancing their technical skills throughout their education. An open-air exhibition park has been created in a beautiful area of our department's garden, featuring wall, column, beam, slab formworks, scaffolding, and connection details. This exhibition, created with the valuable participation of IKSD and its members, includes detailed project drawings, relevant photos, and useful links on this live page. This page can be accessed via a QR code located in the exhibition area and provides access to various useful information through mobile phones and computers.

We would like to express our gratitude to the Scaffold and Formwork Manufacturers Association (IKSD) and its esteemed members for their unconditional support in sharing knowledge. Special thanks to Gürkan Kasap for his hard work in the establishment and preparation stages and to our idea father, Ruhi Tarhan.

Prof. Dr. Ahmet Türer

Department Head

Civil Engineering Department

Middle East Technical University

Ankara

Links:

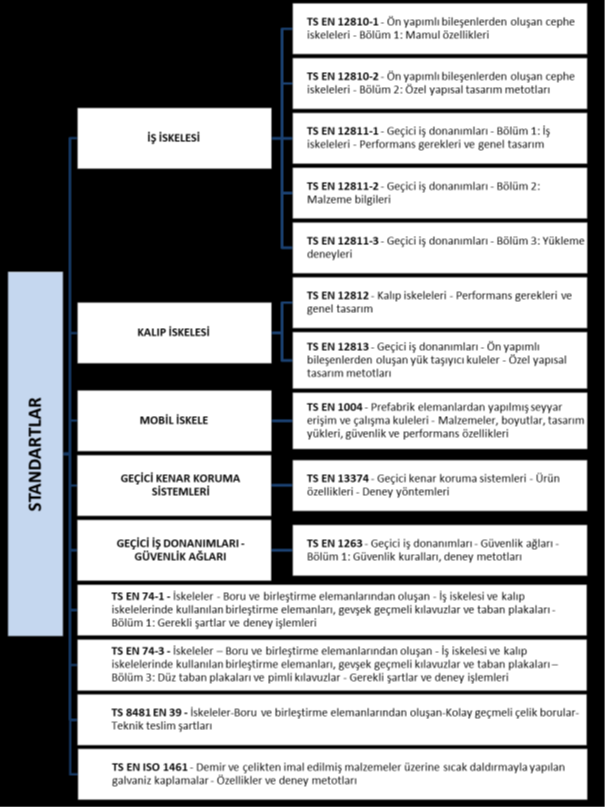

http://www.iksd.com.tr/teknik-bilgi/standartlar/

http://www.iksd.com.tr/teknik-bilgi/sunumlar/

Faydalı Bilgiler:

What is a Formwork?

Formwork is the term for the temporary or permanent molds into which concrete or similar materials are poured. In the context of concrete construction, the falsework supports the shuttering molds.

-

The general name for auxiliary construction elements into which concrete is poured.

-

It allows shaping the concrete. Wood, steel, aluminum, and plastic are generally used materials in formwork production.

-

The formwork surface is in contact with concrete and the choice of formwork surface depends on the desired concrete surface quality.

-

The formwork and the elements supporting the formwork must have sufficient strength to withstand the pressure of fresh concrete. The formwork should be removed once the concrete has achieved sufficient strength.

What makes a good formwork?

-

Should be quick and easy to assemble and disassemble

-

Joints should be easy and fast to connect

-

Should be solved with simple details

-

Must be durable enough to carry the loads applied

-

Should ensure a good concrete surface quality

-

Should be economical

-

Must be leak-proof

-

Should be reusable

-

Must be safe for workers

-

Must be accurate in dimensions

-

Should be lightweight

-

Should not exceed the crane capacity

What is Traditional Formwork?

It is the name given to the traditional wooden formwork system. It consists of 5x10 and 10x10 timbers, and the surface facing the concrete is covered with wood or plywood. Sticks, 10x10 posts, or telescopic props are used for slabs.

What is Industrial Construction Formwork?

Industrial construction formworks consist of prefabricated modules made of steel, aluminum, or plastic. The surface of the formwork facing the concrete is covered with plywood, sheet metal, or plastic-coated, depending on the desired surface quality. Modules can be quickly connected to each other using bolts, locks, or pins. It is much faster and achieves a higher number of repetitions compared to traditional formwork.

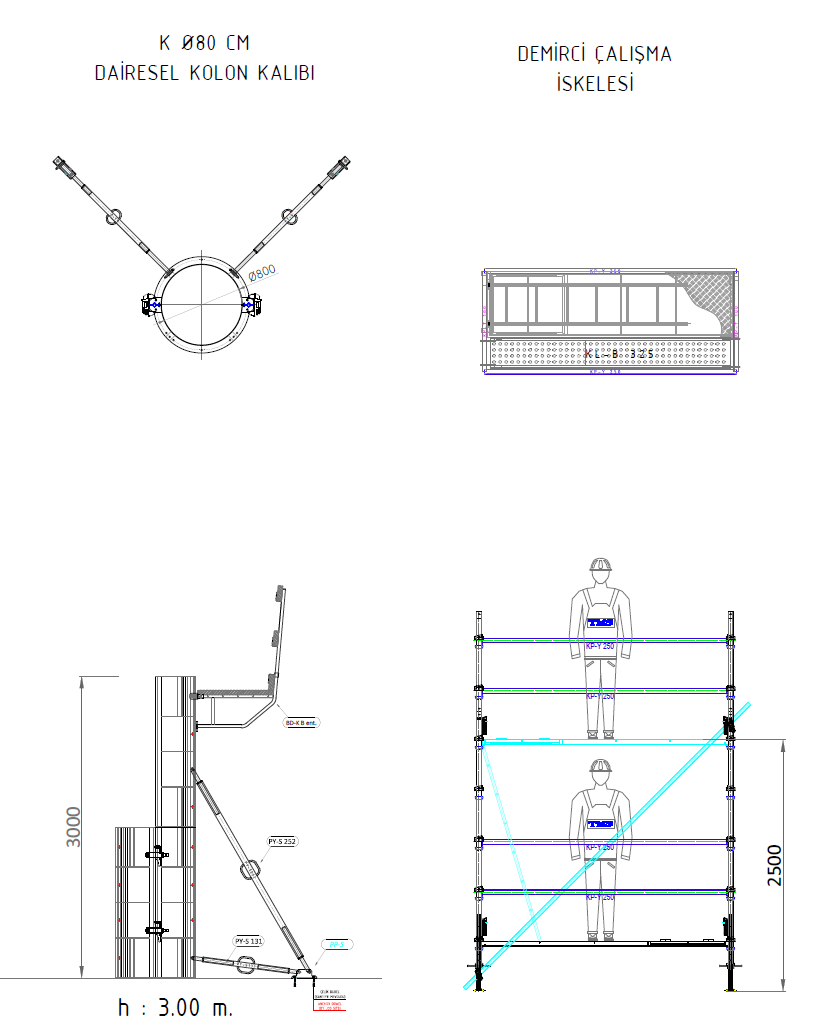

What is a Safe Scaffold?

A scaffold designed and certified to not collapse, overturn, and prevent the worker from falling from height.

Considerations during the installation, use, and dismantling of scaffolding;

I. A scaffolding system manufactured according to standards and holding TS-EN certificates should be used.

II. The most suitable scaffolding system for the job should be selected.

III. The design and static calculations of the scaffolding should be made as it will be used.

IV. The calculation of scaffolds should be made to safely carry the weight of the scaffold itself, vertical and horizontal service loads, wind, and snow loads.

V. Scaffolds should be assembled and dismantled under the supervision of competent technical personnel by scaffolding installation personnel with MYK certification, according to the project.

VI. Periodic inspections of the scaffolds should be carried out at specified intervals.

http://www.guvenliinsaat.gov.tr/

TERMS AND DEFINITIONS USED IN FORMWORK AND SCAFFOLDING SYSTEMS

Formwork

Formwork refers to temporary or permanent molds into which concrete or similar materials are poured. In the context of concrete construction, the falsework supports the shuttering molds until the concrete has cured to the point where it is self-supporting.

Falsework

Falsework consists of temporary structures used in construction to support spanning or arched structures in order to hold the component in place until its construction is sufficiently advanced to support itself. For slab and beam formworks, falsework refers to the shoring that supports the formwork at the required heights, transferring the loads defined in TS EN 12812 to the ground.

Scaffolding

Scaffolding provides temporary platforms used in the construction, maintenance, repair, and demolition of buildings and other structures to create a safe working environment and safe access to the work area.

Temporary Work Equipments

Temporary work equipment includes all types of machinery, hand tools, and other equipment used in a construction project that are not permanently incorporated into the structure.

Conventional Timber Formwork

These are formwork and scaffolding applications where main components such as wooden 5x10s, 10x10s, 2 cm boards, and similar construction timbers are used, joints are typically made with nails, and craftsmanship is a significant factor.

Industrial Formwork

Industrial formwork systems are designed and manufactured in fabrication according to international standards by expert engineers with the aim of increasing safety levels, efficiency, and quality in formwork and scaffolding manufacturing, as well as reducing costs.

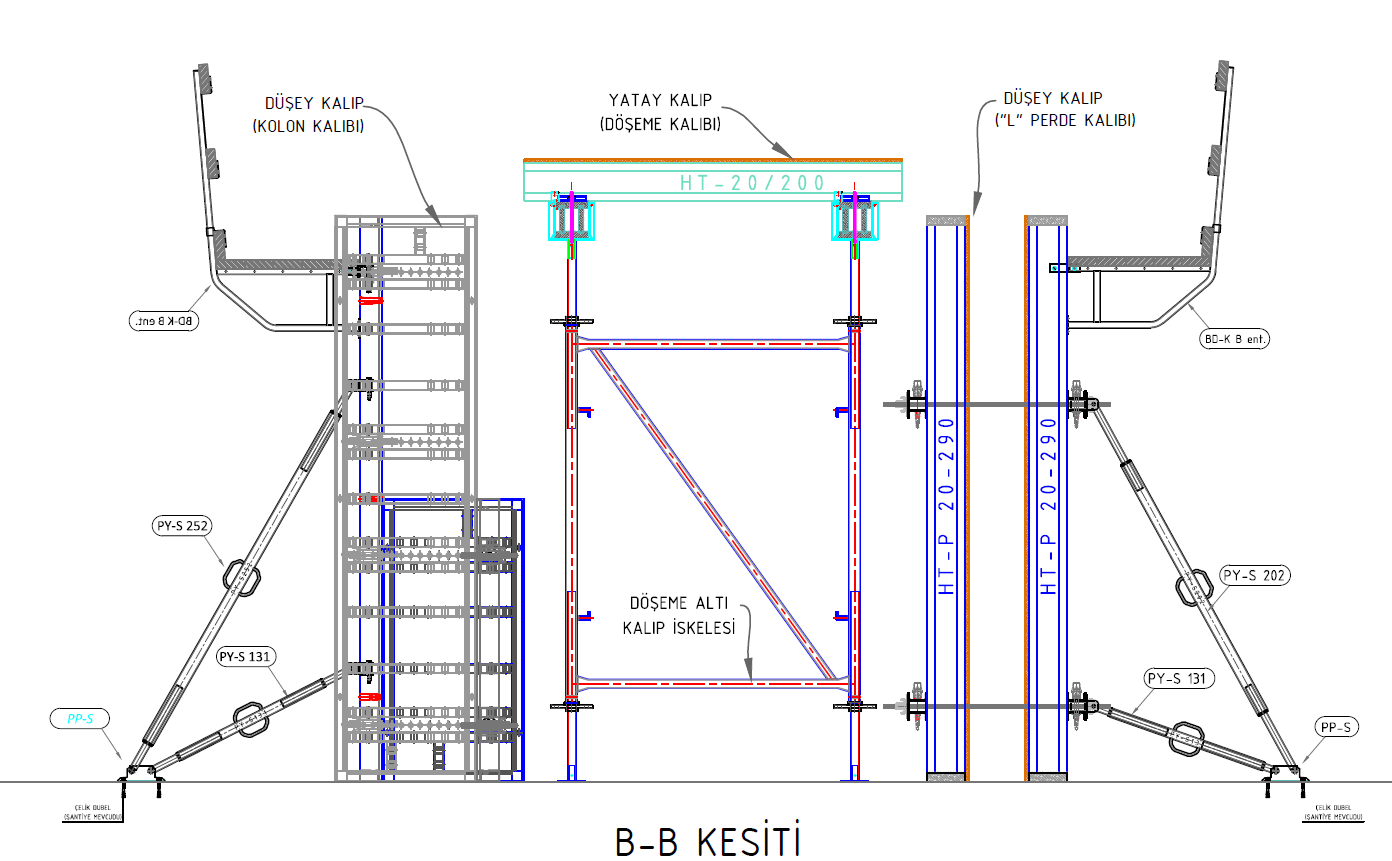

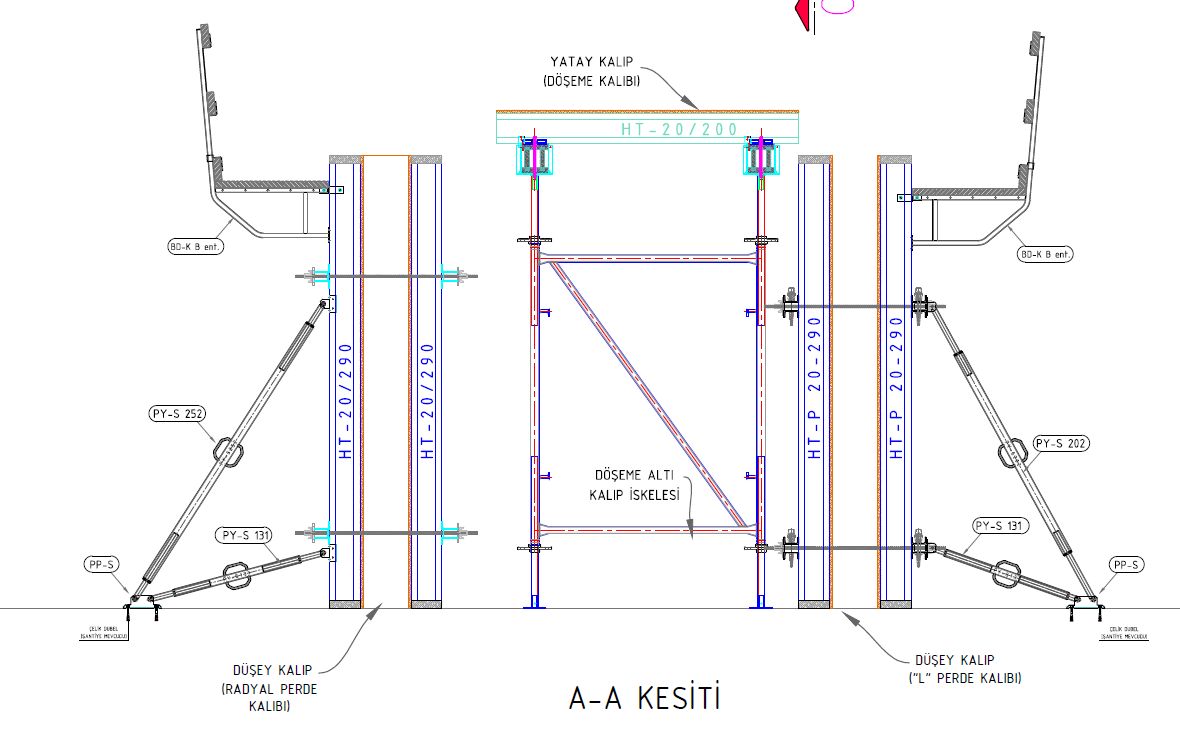

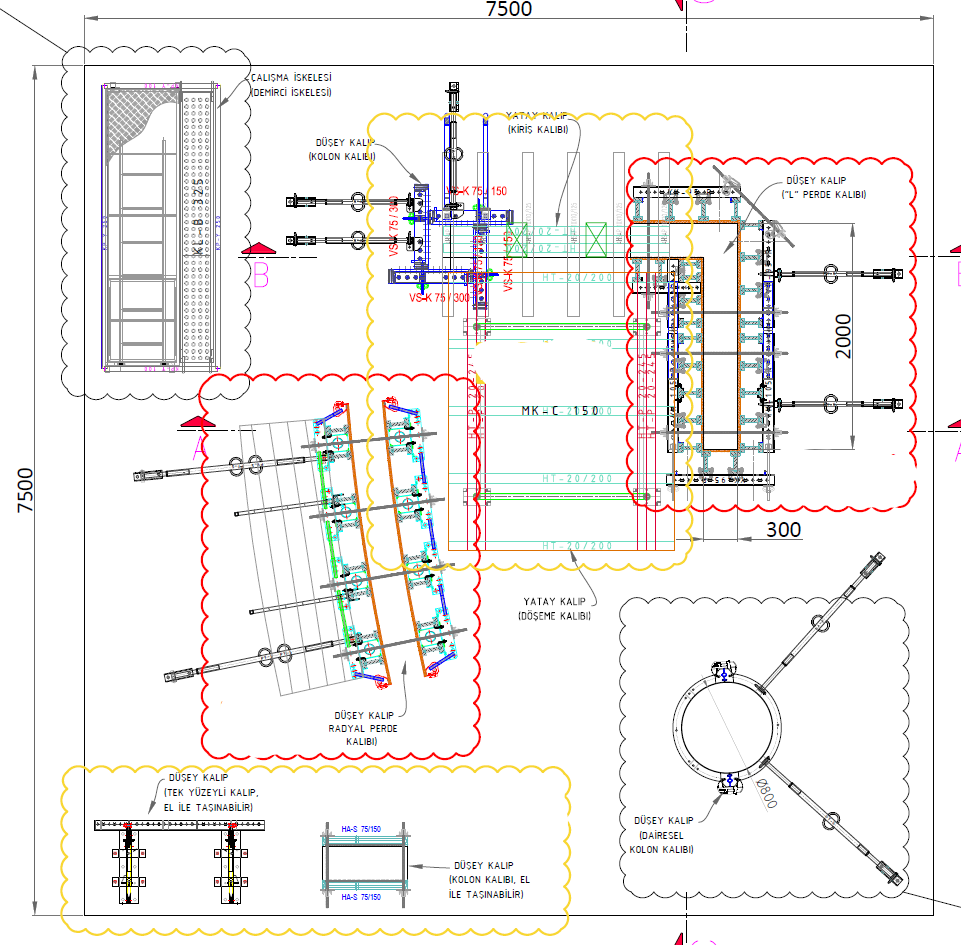

Vertical Formwork

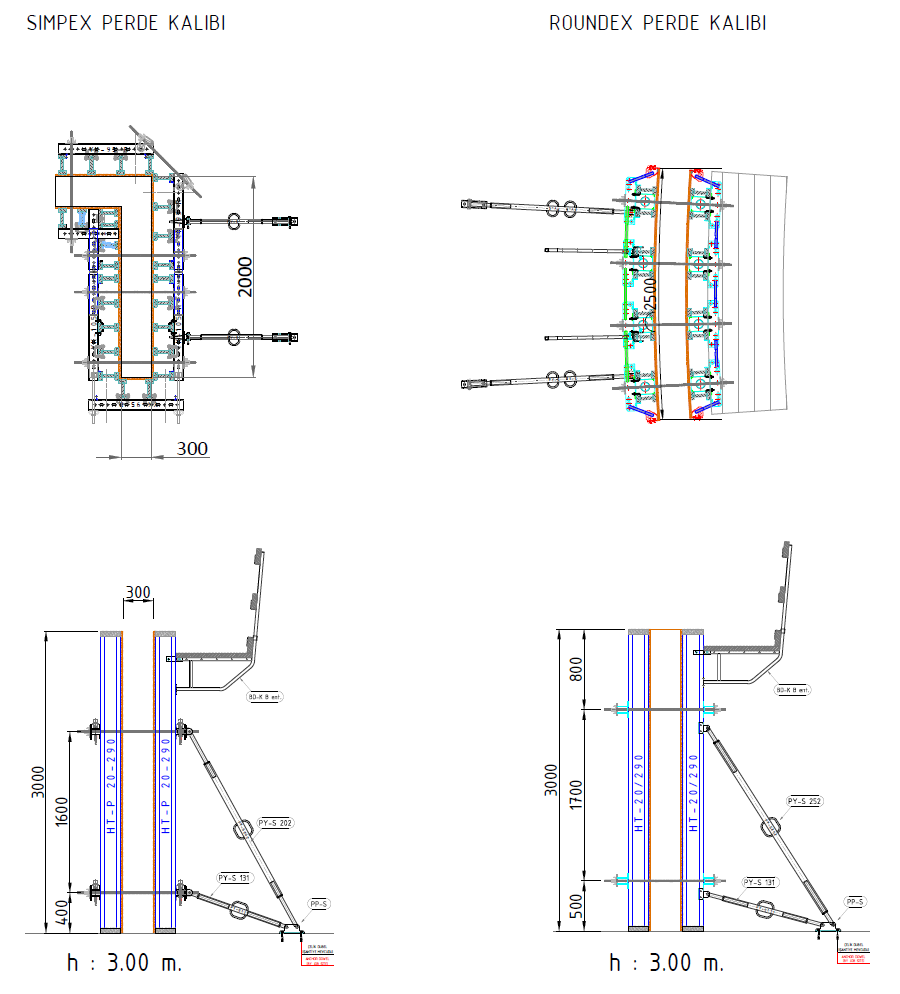

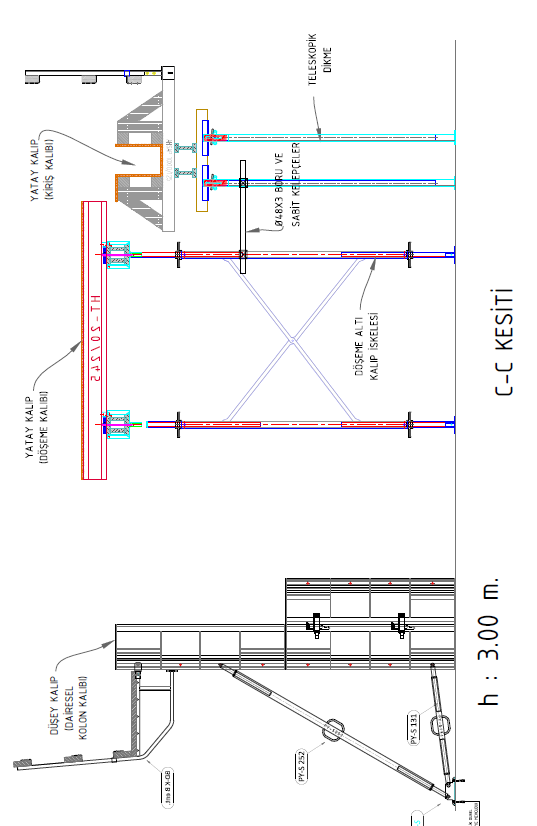

Vertical formworks are used for vertical structural elements such as columns, shear walls, piers, and similar components.

Horizontal Formwork

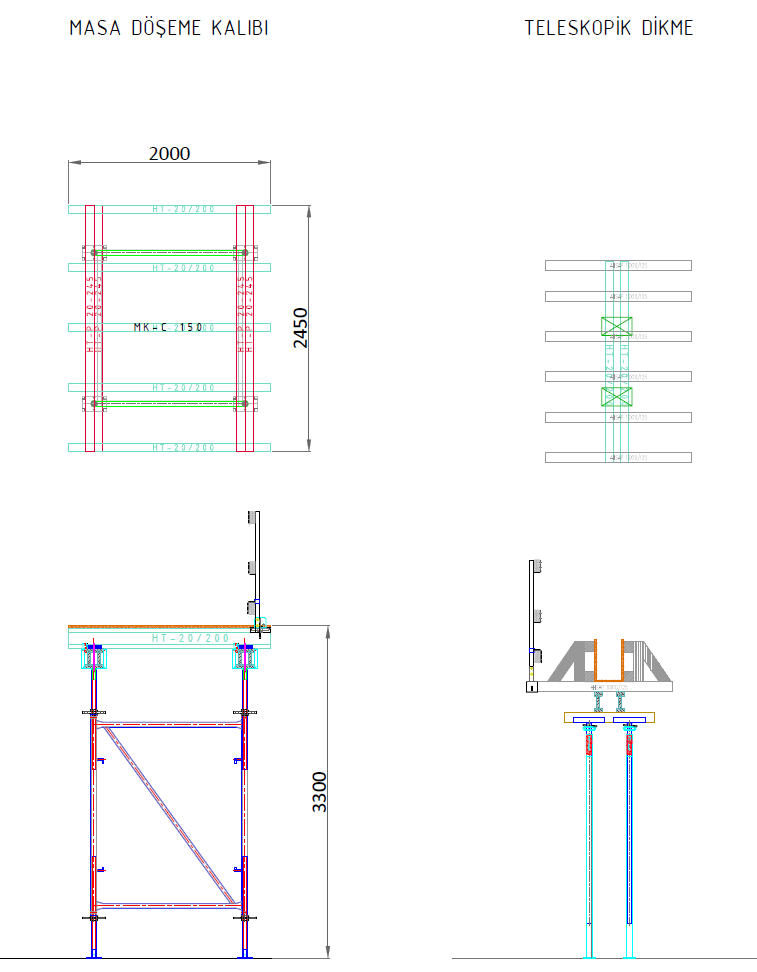

Horizontal formworks are used for "horizontal" structural elements like slabs and beams.

Inclined Formwork

Inclined formworks are used for "inclined" structural elements such as inclined columns, beams, and slabs.

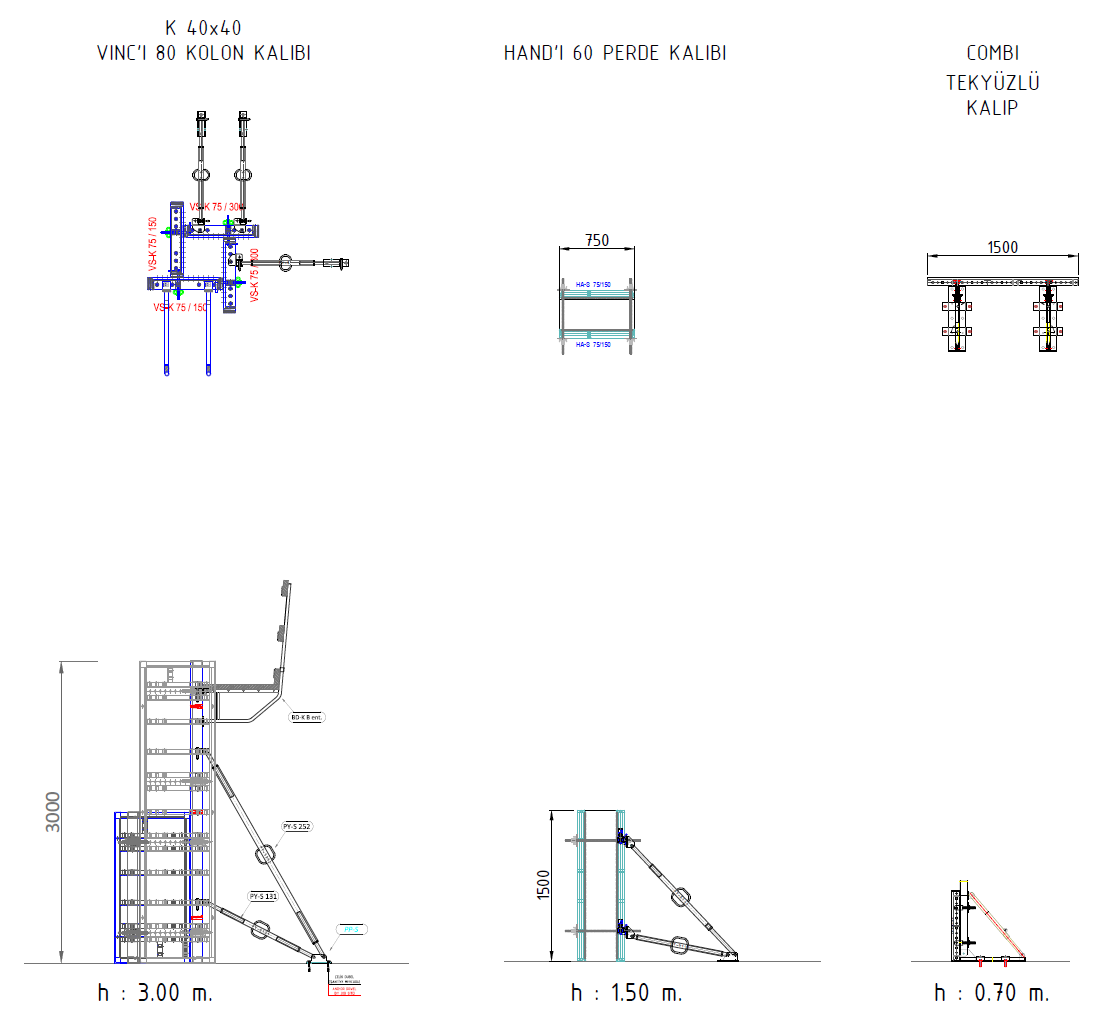

Column Formwork

Vertical formwork systems used to give the required size and shape to reinforced concrete columns.

Panel Formwork

Panel formwork consists of frames with modular dimensions produced from high-strength metal profiles welded together, one side of which is covered with a wooden formwork board or a metal plate. These systems are mass-produced in factories according to international standards, can be used without pre-assembly, and are available for both vertical and horizontal applications.

Monolithic Formwork

Monolithic formwork systems allow the concrete to be poured in one go, using both vertical and horizontal formworks together.

Tunnel Formwork (Residential)

A special monolithic formwork system used in mass housing projects, typically resistant to earthquakes, where vertical structural elements are solved with walls instead of columns.

Tunnel Formwork (Infrastructural)

Formwork systems that allow for the construction of tunnel structures by providing the tunnel shape for concrete pouring.

Precast Formwork

Precast formwork is used in the production of precast concrete elements (columns, beams, slabs, facade elements, etc.) manufactured in a factory setting using the prefabrication method.

Hydro-mechanical Formwork

Formwork systems that can be moved to the next pouring location with the help of hydraulic systems after the concrete casting is completed.

Timber H Beams/Timber Beam

Certified carrier beams with H section, which can be used as carrier beams in both directions in ridge grill formwork systems, are mass-produced in factories according to international standards from wooden raw materials.

Formwork Sheet

They are planar elements used on the surfaces facing concrete in industrial formworks. While wood is generally used in formwork sheets, steel, plastic, or composite materials can also be utilized.

Plywood

Plywood refers to the type of product produced by gluing together thinly peeled layers of wood, with the grain directions of adjacent layers oriented perpendicular to each other, under high pressure. This specific type is designed for use on the concrete-facing surfaces in industrial formworks.

Spindle

Spindles are steel rods or tubes with threads, used as the bottom and top elements of formwork scaffolds and working scaffolds, facilitating the micrometric adjustment of scaffold heights.